The best screen printing machine depends on your usage—manual for beginners, automatic for volume, and hybrid digital setups for flexibility—all ideal for t-shirts, stickers, and small business branding.

Screen printing continues to dominate custom merchandise production across apparel, promotional items, and creative services. With the demand for custom t-shirt printing and promotional branding at an all-time high, selecting the right screen printing machine can be a game-changer, especially for startups and small-scale manufacturers.

Content

Understanding Screen Printing Machine Types

Different needs require different printing setups. While some users prioritize entry-level simplicity, others need automation and speed. Understanding the key types of screen printing machines helps match capability to intended use.

Manual Screen Printing Machines

Perfect for hobbyists, beginners, and low-volume producers, manual screen printing machines are easy to set up and operate. They’re cost-effective and portable—suitable for small workspaces or creative studios.

- Ideal for DIY screen printing

- Low maintenance, budget-friendly

- Great for learning and experimentation

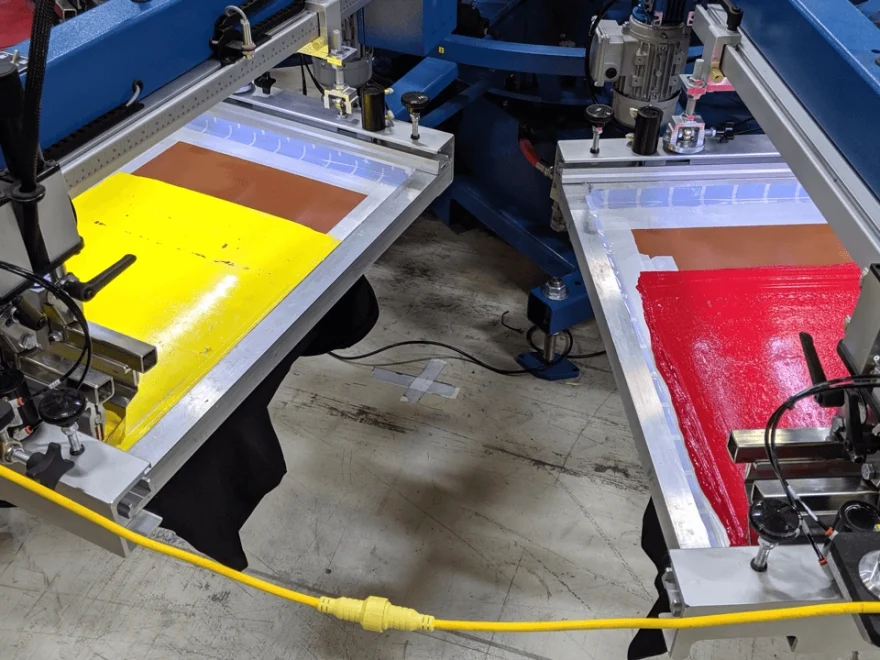

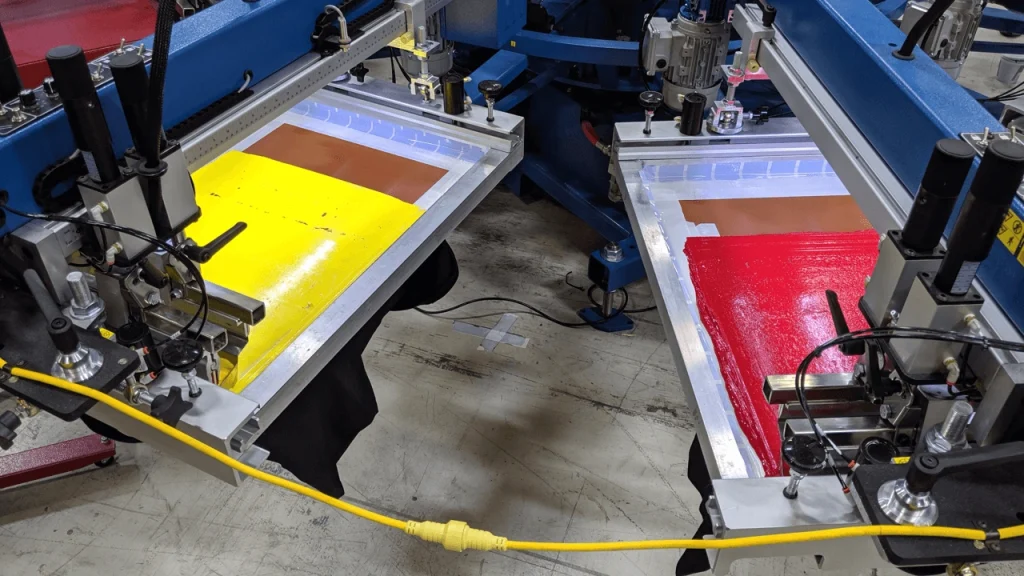

Automatic Screen Printing Machines

For businesses printing hundreds of items daily, automatic screen printing machines deliver speed and consistency. These systems require more space and investment but offer impressive returns through efficiency.

- High-speed and labor-saving

- Preferred for commercial t-shirt printing

- Consistent output with advanced controls

Digital and Hybrid Models

Though not traditional screen printers, digital printing machines integrate seamlessly into custom printing workflows, especially when detail and flexibility are needed. Some businesses even combine digital printing machines with screen printing machines for a hybrid approach.

- Better for detailed, full-color prints

- No need for separate screens

- Used in modern custom printing machines

Top Screen Printing Machine: Quick Comparison

Here’s a curated look at some of the top-rated machines for t-shirts and more.

| Model | Type | Features | Best For |

| Riley Hopkins 150 Press | Manual | Compact, 1-color station | Beginners & DIY |

| ROQ Eco Automatic | Automatic | Touchscreen, high-volume | Commercial printing |

| Vastex V-2000HD | Manual | Heavy-duty, expandability | Small businesses |

| M&R Sportsman EX | Automatic | Servo drive, multi-color | Bulk apparel production |

| Ving 4 Color 1 Station | Manual | Entry-level, affordable | Home-based business |

Each of these screen printing machines comes with specific advantages for budget, productivity, or use case.

Choosing the Right Machine for Your Needs

Define Your Production Volume

Begin by assessing how many units you intend to produce daily. A manual screen printing machine may suffice for under 50 units per day, while automatic screen printing machines are more viable for bulk orders exceeding 100+ units.

Consider Materials and Substrates

What will you print on? Cotton is the most common material, especially in t-shirt printing, but if you’re also producing decals, tote bags, or other formats, opt for a model that handles various substrates. For example, a sticker printing machine often requires different platen setups or screen mesh types.

Budget and Maintenance

Entry-level machines start at a few hundred dollars, while industrial screen printing machines can cost thousands. But ongoing machine maintenance and ink costs should also factor into your decision. Choose models that are easy to clean and come with accessible support networks.

Tailored Machines for Specific Uses

For Small Business Startups

Small enterprises need a blend of affordability and scalability. Machines like the Vastex V-2000HD and Riley Hopkins 250 provide modular add-ons so you can expand as your operation grows. These are ideal printing machines for small businesses entering the apparel or merchandise space.

For Events or Mobile Printing

If you’re servicing concerts, expos, or pop-up shops, portable screen printing equipment is a must. Look for models with compact frames, easy assembly, and low power requirements. A portable screen printing machine allows on-the-go creativity and boosts audience engagement.

For Eco-Conscious Printers

Sustainability is growing in importance. Choose eco-friendly screen printing machines that support water-based inks and minimize waste. The ROQ Eco and M&R Gauntlet series include features that align with green printing practices.

How Digital Printing Fits In

If you require intricate detail and fast turnaround, especially on smaller orders, a digital printing machine may be better suited. These machines skip the screen preparation phase and allow real-time design updates, making them ideal for limited runs or client prototypes.

Why Local Sourcing Matters

While global models are popular, working with regional vendors improves support, training, and delivery speed. Many entrepreneurs look for options like:

- Buy screen printing machines in Faisalabad

- Printing equipment dealers in Punjab

- Local printing machine suppliers in Pakistan

These localized searches not only improve Google rankings but help you access faster technical support and spare parts availability.

Final Thoughts

Choosing the right screen printing machine involves aligning your business goals with machine capabilities. Whether you’re launching a side hustle, running a boutique brand, or scaling up commercial production, there’s a printing solution that fits your workflow, space, and budget. With the surge in custom t-shirt printing, eco-friendly options, and portable screen printers, now is a great time to invest in high-quality, versatile printing technology.

Frequently Asked Questions

What’s the difference between digital and screen printing?

Screen printing machines push ink through stencils for bold, durable prints, while digital printing machines apply ink directly to the material like a regular printer, offering finer detail and color gradients.

Can I print both stickers and t-shirts with one machine?

Yes, many screen printing machines are versatile enough for textiles and flat surfaces, but using dedicated platens or attachments ensures better results.

What maintenance is required for screen printing machines?

Regular cleaning of screens, checking platen alignment, and lubricating mechanical parts are essential. Preventive maintenance prolongs machine life and maintains print quality.

Is it possible to run a printing business from home?

Absolutely. With a compact screen printing machine, a few screens, and basic training, many entrepreneurs have launched home-based t-shirt printing businesses with minimal overhead.

How much should I spend to start?

Starter kits range from $300 to $3,000. Begin with a manual screen printing machine and expand as you secure clients and increase volume.

Jerald is a blogger with a passion for technology who has been writing about the latest in the world of gadgets and gizmos. They are an avid reader of Science-Fiction novels and love to spend time with their wife and kids.